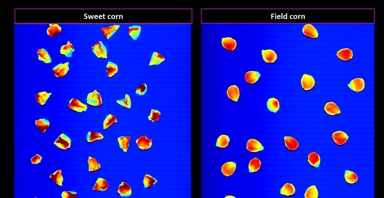

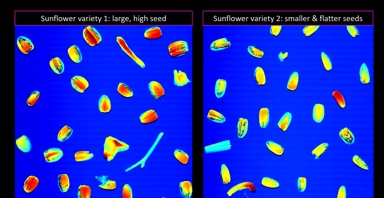

See how imaging reveals hidden seed traits.

Cleaning & Processing

Quickly quantify the quality of each seed, set the right sorting parameters, and prevent valuable seeds and lots from going to waste.

Cut lead times with rapid bulk scans.

Get seed quality and purity readouts within minutes, replacing slow and indirect germination tests.

Calibrate machines with real data per lot.

Characterize the full distribution of seed traits before processing, so you know exactly what to sort and how - avoiding costly reprocessing.

Define the border between usable and non-usable seeds.

Use predictive models to set precise cut-offs and trade-offs, maximizing usable seeds without compromising quality.

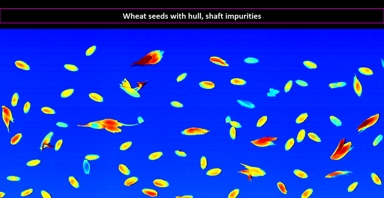

Replace or complement crucial processes with one advanced sorter.

One advanced sorter for cleaning, grading, and 3D sorting, covering both external and internal seed quality.

From test to truth in minutes

With SeedTelligence, you no longer have to rely on slow germination tests or external traits alone. Our technology delivers fast, in- or at-line seed quality insights and 3D sorting capabilities, allowing you to clean, grade, and optimize every lot with precision. This allows you to save seeds, reduce waste, and decrease pressure of central facilities.

Unlock the power of phenotype data, from seed to plant.

Our interconnected technologies generate objective, explainable data and convert it into decisions that optimize operations across your organization.

3D Xray CT phenotyping of seedlings

phenoTest

Assess final lot quality of germination, homogeneity and vigor for confident blending and release.

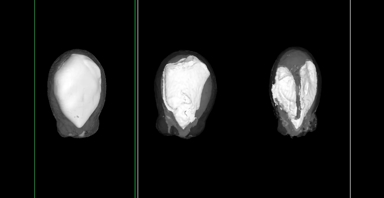

3D Xray CT phenotyping of seed bulks

phenoCheck

Measure seed quality within minutes to steer processing in-line and monitor quality continuously.

3D Xray CT phenotyping of seeds & seedlings

phenoMatch

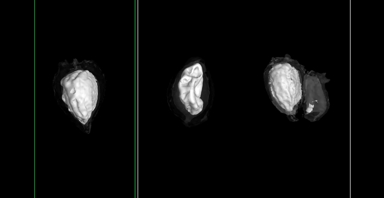

Sort for both external and internal 3D seed quality in one high-throughput machine.

3D Laser 2D Xray seed sorter

phenoScort

Sort for both external and internal 3D seed quality in one high-throughput machine.

Find answers on how SeedTelligence can transform Production & Supply Chain.

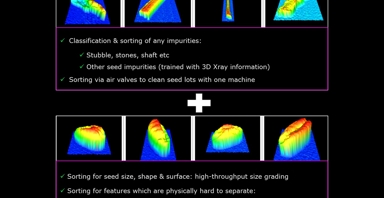

What are the advantages of combined 3D laser / 2D X-ray sorting?

It enables classification by shape, surface features, and internal structures, achieving separations not possible with conventional methods.

What is the sorting throughput in industrial use?

Our sorters process around 300,000 objects per minute in industrial use, with new systems expected to match or exceed this speed. Also smaller lower throughput options are possible.

Is SeedTelligence suitable in a deglobalizing supply chain?

It enables distributed operations: local hubs can analyze on-site, while data is harmonized centrally for global decision-making.

What happens with my data?

All data remains on your premises. Only with explicit consent may it be used for specific support or development activities for your system.

Who are the typical clients of SeedTelligence?

SeedTelligence solutions are designed for seed companies, plant breeders, and crop protection companies that require reliable, high-quality seed and seedling data. These can either be small, mid- or large size organizations.

Other use cases to unlock

Production & Supply chain

With phenoCheck or phenoScort, seed lots can be cleaned and sorted locally, while integrated global data ensures consistency before shipping to central sites.

Quality Testing & Sales

Use predictive models and objective standards to steer processing decisions based on market demand.

Breeding & R&D

Apply better data and tools to save as much material as possible, especially in difficult years.

End-to-End

Connect insights across functions to drive efficiency and output.